OBO Bettermann GR-Magic® Mesh Cable Tray - German European School of Singapore

© AHK Singapur

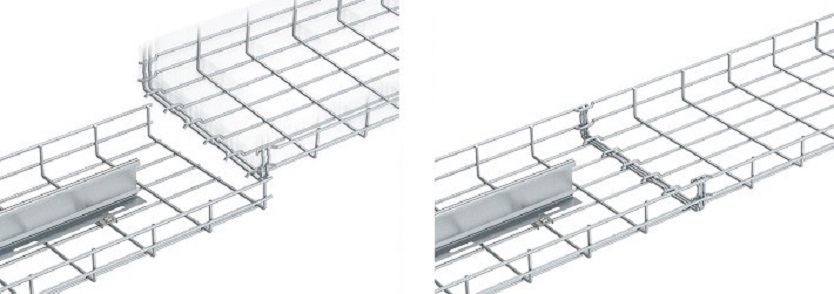

Thanks to the clever, practically tested connection technology, all the key system components, such as trays and fittings, can be snapped on without drilling.

For a purely straight connection, neither connection components nor installation tools are required. This means that there is no need to store connection parts which saves costs. The new GR-Magic® mesh cable tray really speeds up installation and manages this with no loss of stability and load-bearing capacity. Load tests show that GR-Magic® systems can fully match up to traditional screw connections. The GR-Magic® system can also be fastened on the bracket without screws.

Successfully installed at the German European School of Singapore. Conventional cable tray system uses bolts and nuts for the connection between each cable tray and is a very labour intensive installation activity. OBO’s MAGIC cable tray system, from the trays to the fittings, is the world‘s first system in which all the major components are equipped with the innovative MAGIC Snap-On connector. The spring elements are permanently attached to the components, so they do not get lost. Coupled with better structural strength and mounting possibilities, lesser mounting supports are needed thus further reducing the installation time and labor resources needed.

On average, an overall savings of 35-40% on installation time is achieved with this technology.

OBO Bettermann GR-Magic® Mesh Cable Tray - German European School of Singapore

© AHK Singapur

About the Energy Efficiency Award Challenge

The Energy Efficiency Award Challenge was organized by the Singaporean-German Chamber of Industry and Commerce in June 2018. The Award Challenge intended to promote successful German-Singaporean partnerships in the building sector. The five projects that have been selected show how innovative German energy-efficient solutions have led to increased building quality, reduced energy costs and lower CO2 emissions levels in Singaporean buildings.

The one-day event comprised two site visits in the morning, a workshop in the afternoon and an evening reception. At the evening reception three of the five projects that made it to the finals have been awarded for the use energy-efficient technologies “made in Germany”.

The Energy Efficiency Award Challenge is part of the German Energy Solutions Initiative of the German Ministry for Economic Affairs and Energy to recognise the positive impact German solutions have on Singapore’s efforts to become more energy efficient.