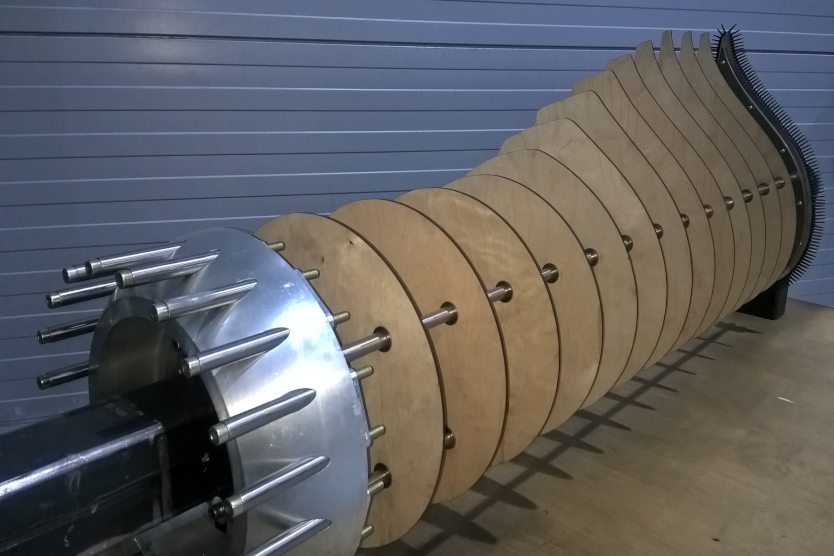

Downscaled model of the segment of a rotor blade. Even such rotationally non-symmetric parts shall be wound more effectively thanks to the new manufacturing process.

© CirComp GmbH

Many research aims to improve the industrialisation process of components for wind turbines, such as rotor blades. The rotor blade roots are also targeted by WindRoot: The comparatively low-cost filament winding technique, in which the rotor blade roots aren’t layered but wound separately from different layers of material, could significantly reduce the manufacturing costs of wind power plants. Rotor blades currently make up 30% of the total manufacturing cost of wind turbines. The rotor blade roots, in turn, make up about 25% of the rotor and are therefore an ideal target for improvements in the manufacturing process.

The quality of the rotor blades could also be improved by reducing the number of production steps and enhancing the automation of the manufacturing process by winding the layers of material. The planned division of the different steps involved in the rotor blade production could offer additional advantages, as the integration of in-house and subcontracted suppliers in the manufacturing process could help to resolve bottlenecks in production.

The innovative rotor blade roots are being developed by the Fraunhofer Institute for Wind Energy Systems (IWES) in collaboration with the project-partners CirComp GmbH, LSA Logistik Service Agentur GmbH and WINDnovation Engineering Solutions GmbH. The cost-effectiveness of this production technique is being tested on a prototype. In addition, the researchers will also investigate the impact of the altered manufacturing process on industrialisation production and the usability of the winding technique in other areas of rotor blade production. This will also involve examining potential cost savings of the logistics of this new production method.

The project WindRoot is being funded by the Federal Ministry for Economic Affairs and Energy (BMWi) between January 2017 and December 2019.