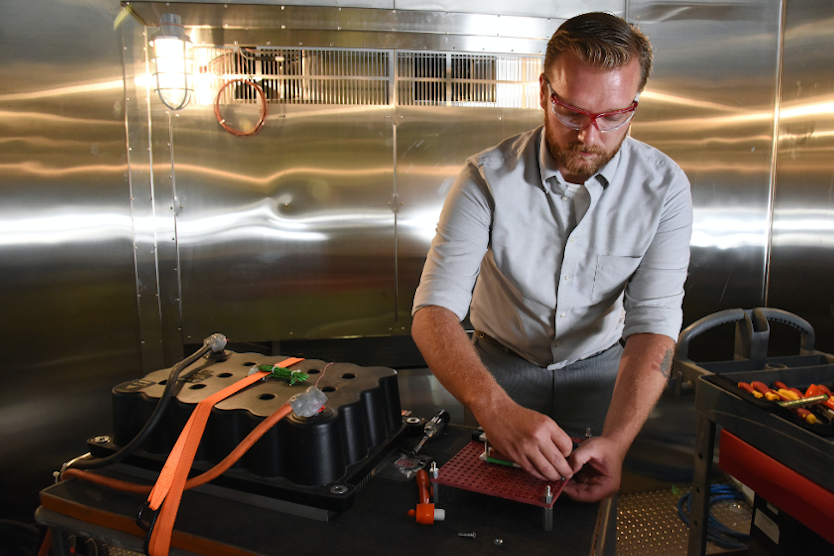

The “KontElPro” research network has the goal of developing eco-friendly and economical processes for producing battery electrodes in Germany.

© Unsplash

Artificial intelligence (AI) is increasingly being used to assist in Germany’s transition to a carbon-neutral energy supply. In the latest instance, The Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) has set up the “KontElPro” (Continuous Electrode Production) research network with the goal of developing eco-friendly and economical processes for producing battery electrodes inside Germany.

Battery electrodes and cells are a key technology for electromobility and energy storage. They are mainly produced in Asia using an energy-intensive manufacturing technique: an electrode paste is applied to a thin metal foil and the toxic solvent is then extracted over time in a drying oven. By contrast, KontElPro will explore non-toxic, solvent-free electrode production by means of extrusion and a subsequent dry transfer process.

Machine learning, an area which the ZSW excels in, will be used to optimise and control the new manufacturing processes. Other research partners in the network include the Fraunhofer Institute for Manufacturing Technology and Applied Materials Research (IFAM), the Fraunhofer Institute for Material and Beam Technology (IWS) and the Fraunhofer Institute for Chemical Technology (ICT).

"With the latest AI methods, we can record, evaluate and control all the important factors influencing the quality of the electrodes during production and thus ensure a consistently high quality of the electrodes throughout the entire process," explains Anton Kaifel, team leader of the AI and Machine Learning department at ZSW in a press release.

The Federal Ministry of Education and Research (BMBF) is funding the KontElPro project with EUR 1.8 million as part of the research cluster "Intelligent Cell Production" (InZePro).