Scientists at the Fraunhofer Institute for Building Physics (IBP) have joined forces with the German Aerospace Centre (DLR) and several industrial partners to ensure the future of electromobility in Germany is green.

© Unsplash

New petrol and diesel vehicles will be outlawed by the EU in 2035, and Germany’s auto industry must be ready to meet the rising demand for electric vehicles (EVs). But the production of electric batteries requires large amounts of sought-after raw materials such as lithium, which is typically imported and is therefore not considered sustainable. Another solution is to recycle end-of-life EV batteries, but the process takes considerable effort and is only partially successful.

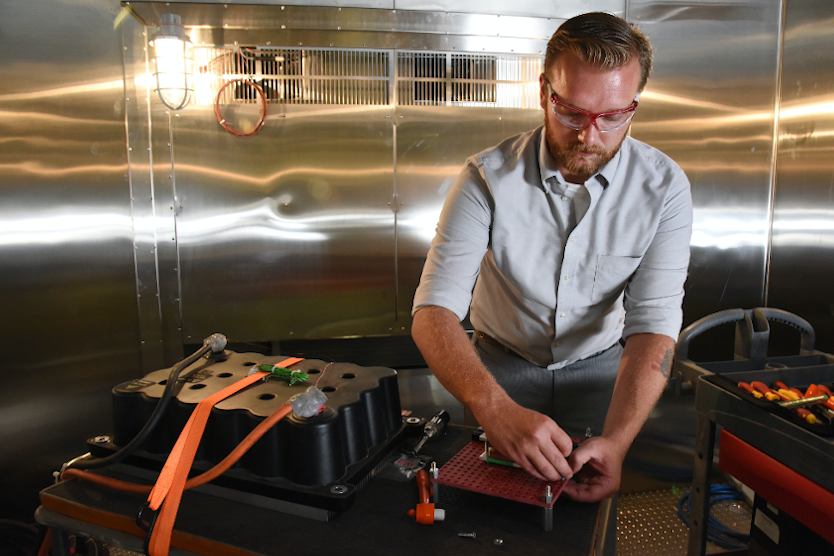

Scientists at the Fraunhofer Institute for Building Physics (IBP) have therefore joined forces with the German Aerospace Centre (DLR), industrial partners Zeppelin Systems, UniverCell Holding and Portuguese company BB&G Alternative Worldwide Environmental Solutions to ensure the future of electromobility in Germany is green. The Kolibri research project is funded for three years from September on by the Federal Ministry of Economic Affairs and Climate Action and coordinated by RCB Nanotechnologies.

Kolibri will develop safer, high performing batteries that are completely recyclable. Improvements in materials science is key: the R&D teams will focus on electrodes and the industrial partners on electrolytes. For example, the anodes will be made from a “highly porous carbon aerogel” produced from biomaterials developed by DLR, according to the press release. Better conductivity and circularity is achieved by combining the aerogel with carbon black (rCB) recovered from used tyres.

However, the rCB must be cleansed of contaminants before it’s used to make new batteries. The Fraunhofer team is developing specialist techniques to achieve the high purity required. UniverCell brings its knowledge of production processes, so the results can be scaled up to industrial levels pilot plant will eventually be built at IBP and the technology will be demonstrated in a variety of electric applications including cars and laptops.