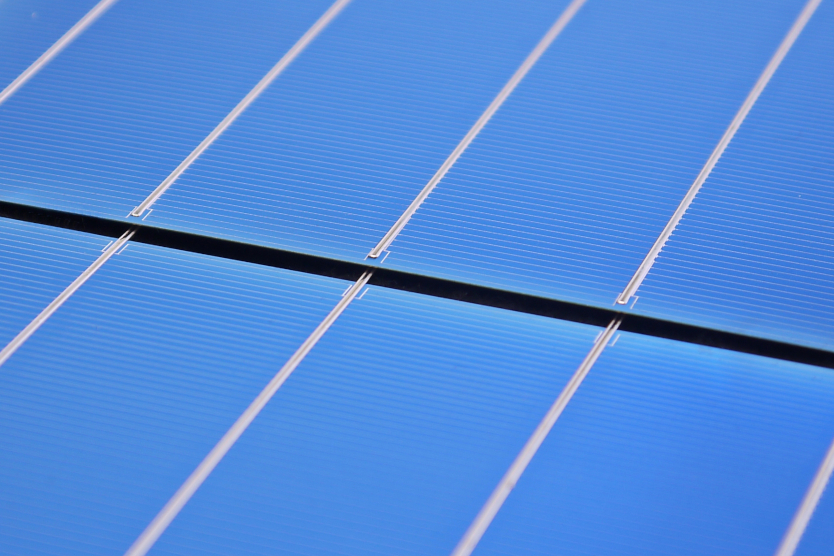

The selectively coated cell connector developed by Fraunhofer ISE

© Fraunhofer ISE

A revolutionary new plastic called Bipolymer can generate green energy from industrial waste heat or solar power. The polymer was developed by Poligy, a start-up based in Düsseldorf, which has won several accolades for innovation and is a candidate for this year’s Energy Transition Newcomer, an annual competition held by German Renewable Energy Federation (BEE).

The man behind the invention and Poligy’s co-founder is commercial chemist Martin Huber, who explains the significance of his Bipolymers to AZO Cleantech magazine: “Until now, there has been no cheap technology alternative that can produce green electricity from waste heat at temperatures between 50 °C and 200 °C,” he says.

So how does it work? The Bipolymer consists of two-ply plastic strips which form a wheel in the thermal engine application, or a band in solar panels. One strip contracts, while the other expands, according to the temperature (hot or cold), which creates movement in the belt or wheel and generates electricity.

Bipolymers have a number of advantages: they are inexpensive to produce and to operate (Poligy say electricity could be generated for as little c.€0.05 per kWh) and they can be recycled more cheaply than solar panels. Speaking at the BEE awards pitch in January, Huber underlined the opportunity: “Considering that 45% of industrial heat worldwide is released unused into the atmosphere, the potential is enormous. According to a study by Global Market Insights Inc. from early 2019, the global waste heat market will grow from $40 billion in revenue in 2018 to over $80 billion in revenue in 2025.”

Poligy hopes its Bipolymers will be used widely. According to the German Energy Agency, German industry could save around 37 million tonnes of climate-damaging CO2 and €5 billion a year by avoiding and using industrial waste heat, tapping a heat potential of 125 terawatt hours.