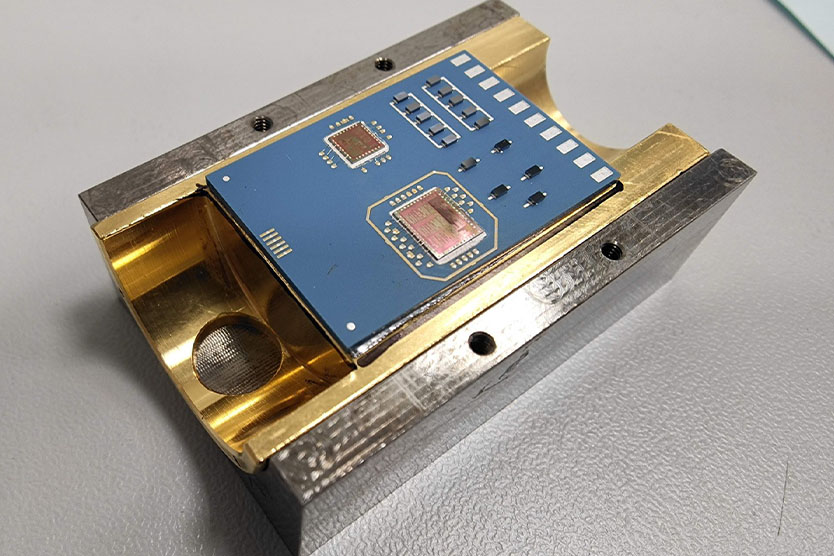

Ceramic circuit board with integrated circuits resistant to high temperatures.

© Fraunhofer IZM

In industrial processes today, so much depends upon tiny sensors. They can identify malfunctions on the production line, sense overheating and other environmental disruptions. But they are by their nature sensitive and do not last long in harsh environments such as the insides of power plants, wind turbines or boreholes.

This problem was deemed serious enough to justify a coordinated effort from eight Fraunhofer institutes this year to develop the first highly robust sensors for hostile and unstable environments and a technology platform for building and testing them. They called it Project “eHarsh”.

The project coordinator, Holger Kappert from the Fraunhofer Institute for Microelectronic Circuits and Systems (IMS), explains why such small solutions require such a massive effort: “We know a lot about heat-resistant ceramics and we have the ability to test material properties and produce robust microelectronic circuits. On our own, though, none of us were capable of creating this type of sensor. It was only through cooperation and the combination of many individual technologies that we were able to succeed.”

The team first focused on applications with high temperatures and pressures such as turbines and boreholes. In such cases, the sensor elements must be made from ceramic that can resist temperatures of up to 500 degrees Celsius and the internal electronics should withstand around 300 degrees Celsius. The novel sensors can also withstand pressures of up to 200 bar, which makes them suitable for use in geothermal systems for pumping subterranean heat into buildings.

Beyond energy tech, the platform could also help machine manufacturers to test the limits of their sensors to reduce testing time and increase service life. “Overall, the interdisciplinary nature of ‘eHarsh’ has allowed us to successfully develop a technology platform for robust sensor systems for many different uses,” summarises Kappert in the press release.