Lux Chemtech is making an important contribution to the circular economy for semiconductors, solar technology or lithium, which is in high demand.

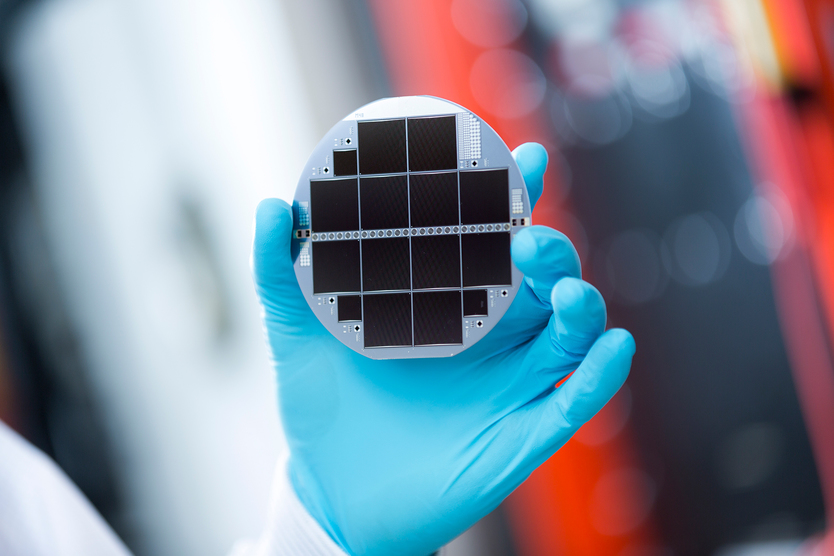

The demand for photovoltaic (PV) technology is rising rapidly across Europe. While that’s good news for energy transition, it means an even tighter squeeze on the highly sought-after raw materials including silicon, gallium, indium and lithium that are used to make solar systems. Now the Freiberg-based company Lux Chemtech has developed a process for recycling photovoltaics on an industrial scale.

Lux Chemtech is part of the international Photorama consortium that received EU funding to develop the techniques for recovering secondary raw materials from end-of-life modules. The start-up has patented technology for cleanly separating critical and valuable metals using chemical-physical processes, that can then be reused for manufacturing domestically. The team’s efforts have won the company the Cluster Award Chemistry/Plastics of the 18th IQ Innovation Award Central Germany.

Jörn-Heinrich Tobaben, managing director of Metropolregion Mitteldeutschland Management GmbH, commented on the jury’s decision in an article in PV Magazine: "Many of the resources on which the high-tech industry or the energy turnaround are built are finite, and the market for rare metals is competitive. With increasing demand, solutions for effective recycling of these valuable raw materials are urgently needed."

Apart from achieving the purity that’s needed for high-tech applications, the start-up’s big breakthrough was developing a recycling process that can be scaled up, thereby making a significant contribution to the circular economy and reducing Germany’s reliance upon imports.